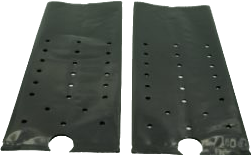

Specifically for nurseries and greenhouses, TDI places custom vent holes in plant grow bags, lay-flat tubing, sheeting, and more. As such, it is an effective way to optimize air flow while meeting specific requirements. Being a manufacturer of plastic products, we understand the importance of tailored solutions for your agricultural packaging needs.

What are Custom Vent Holes?

In simple terms, they are openings designed to allow the escape of gas or air.

Custom Vents

At TDI Custom Packaging, we offer the following vent options for our nursery and greenhouse partners:

1. Vent Hole Spacing

In TDI’s production facility, we punch openings in locations that maximize air flow efficiency.

In TDI’s production facility, we punch openings in locations that maximize air flow efficiency.

These openings can be placed close together or further apart, but they are usually arranged in rows for consistency.

2. Size:

The size of each vent hole determines the rate and volume of air passing through. Smaller openings allow for a limited amount of gas or air at a slower speed, while larger holes enable faster flow.

The size of each vent hole determines the rate and volume of air passing through. Smaller openings allow for a limited amount of gas or air at a slower speed, while larger holes enable faster flow.

3. Location:

Essentially, vent holes can be positioned anywhere on the packaging product—towards the top, middle, or bottom. They can also be grouped vertically or horizontally in one or multiple rows, depending on the desired effect.

4. Quantity:

In addition to spacing, size, and location, you can choose the ideal number of eyelets for your specific needs. The quantity can vary from just a few to several openings.

Products with Custom Vents

Custom vents provide significant advantages in promoting optimal growth and productivity for agricultural products, such as:

Plastic Grow Bags:

Plastic Grow Bags:

Vent holes in grow bags are crucial for maintaining healthy root systems. They enable proper drainage, preventing waterlogging and root rot.

These holes also aid in oxygenating the roots, ensuring they have enough oxygen for respiration. This oxygenation process is vital for strong root development and overall plant health.

With effective drainage and oxygenation, plants in grow bags can thrive, resulting in optimal growth and yield.

Air Flow Tubing:

Air flow tubing optimizes greenhouse heating and cooling by controlling ventilation, temperature, and humidity. It distributes conditioned air efficiently, promoting proper circulation.

Air flow tubing optimizes greenhouse heating and cooling by controlling ventilation, temperature, and humidity. It distributes conditioned air efficiently, promoting proper circulation.

During hot weather, lay-flat air ducting expels excessive heat and brings in fresh air, while in colder seasons, it distributes warm air evenly. Effective airflow promotes plant growth, energy efficiency, and sustainability.

Sheeting Or Film:

Custom venting plays a vital role in agricultural films like mulch film. By regulating temperature and moisture levels, these films protect growing crops while promoting healthy development.

Controlled gas exchange facilitated by custom vents helps maintain an ideal microclimate, reducing the risk of disease and optimizing yield.

Article by BIS Research: “Making a Sustainable use of plastic in the Agriculture Industry” >>>

Custom Vents By TDI

By incorporating custom venting solutions into agricultural packaging, TDI empowers growers and greenhouse operators to optimize air flow, enhance productivity, and achieve superior results in their operations.

By incorporating custom venting solutions into agricultural packaging, TDI empowers growers and greenhouse operators to optimize air flow, enhance productivity, and achieve superior results in their operations.

The cost to add in custom vent holes is not significant and can be an economical packaging solution.